BIM–M 2015 Symposium, St. Louis, MO (Collaborators: Dr. Franca Trubiano, Taylor Knoche, Dr Russel Gentry)

University of Pennsylvania

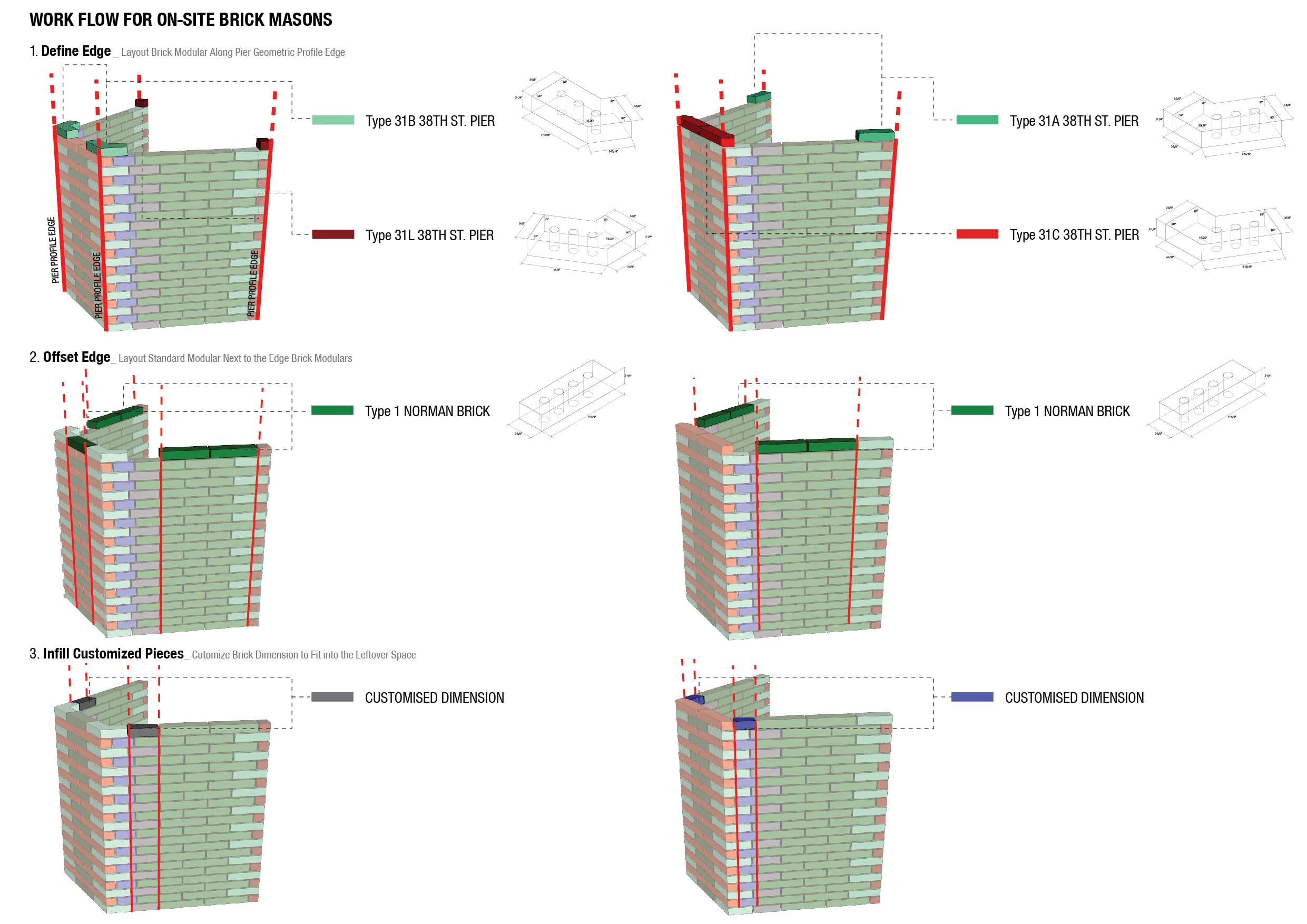

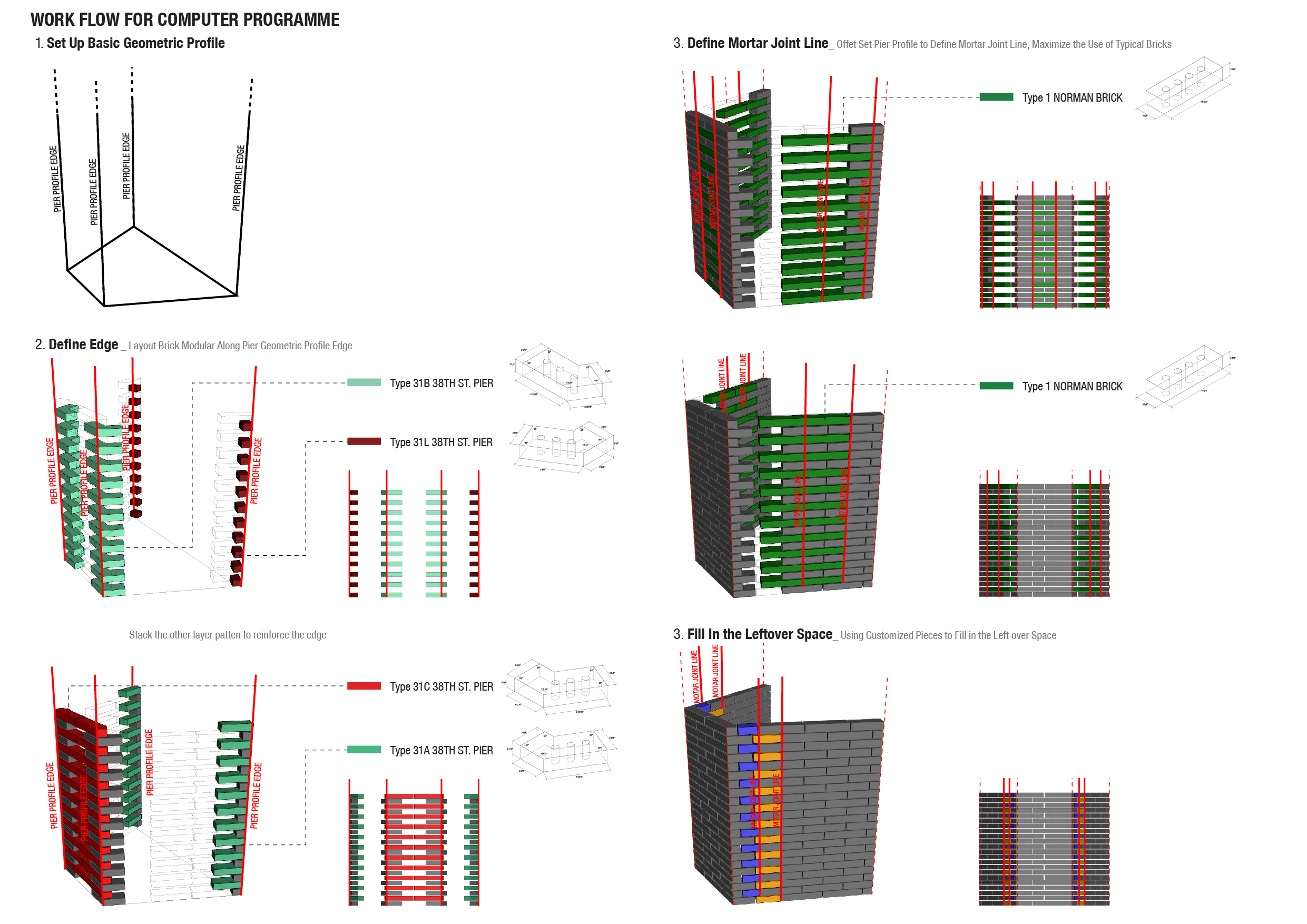

Contribution: Analysing and modelling existing custom masonry pattern, designing workflows for masons and computer program.

Interviewing statkeholders, collecting and sorting data.

Tags: User Experience Design, Digital Fabrication, Design Research, Materials

Contribution: Analysing and modelling existing custom masonry pattern, designing workflows for masons and computer program.

Interviewing statkeholders, collecting and sorting data.

To research and identify the range of brick and stone masonry workflows used in the construction of a signature building – Jon M. Huntsman Hall -- and to identify future improvements to existing Building Information Modeling software that would augment the industry’s capacity to adopt BIM in the design and construction of a greater number of custom masonry buildings.

Design + Building Project Workflow

Design + Building Project WorkflowInterviews were conducted with project Architects + Masonry Sub-Contractors

• The project was designed by KPF Architects using Microstation in 2D.

• There was no manner or form of BIM used in conceiving or building the project in 2001.

• 2D drawings (plans and sections) and on site instructions were given directly to the masonry Sub-contractor, Dan Lepore & Sons

• Both Architect and Sub Contractor reported an excellent collaborative environment. The focus on design details on the part of the architect was matched by an equal focus on construction craftsmanship on the part of the masonry subcontractor.

• The Architect had a dedicated architect who resolved all of the non-standard dimensioning issues attendant to the masonry bonding design with its non- custom geometry and non-orthogonal masonry details. This individual was the ‘go-to’ person for all revisions and coordination.

Modelling the Custom Geometry

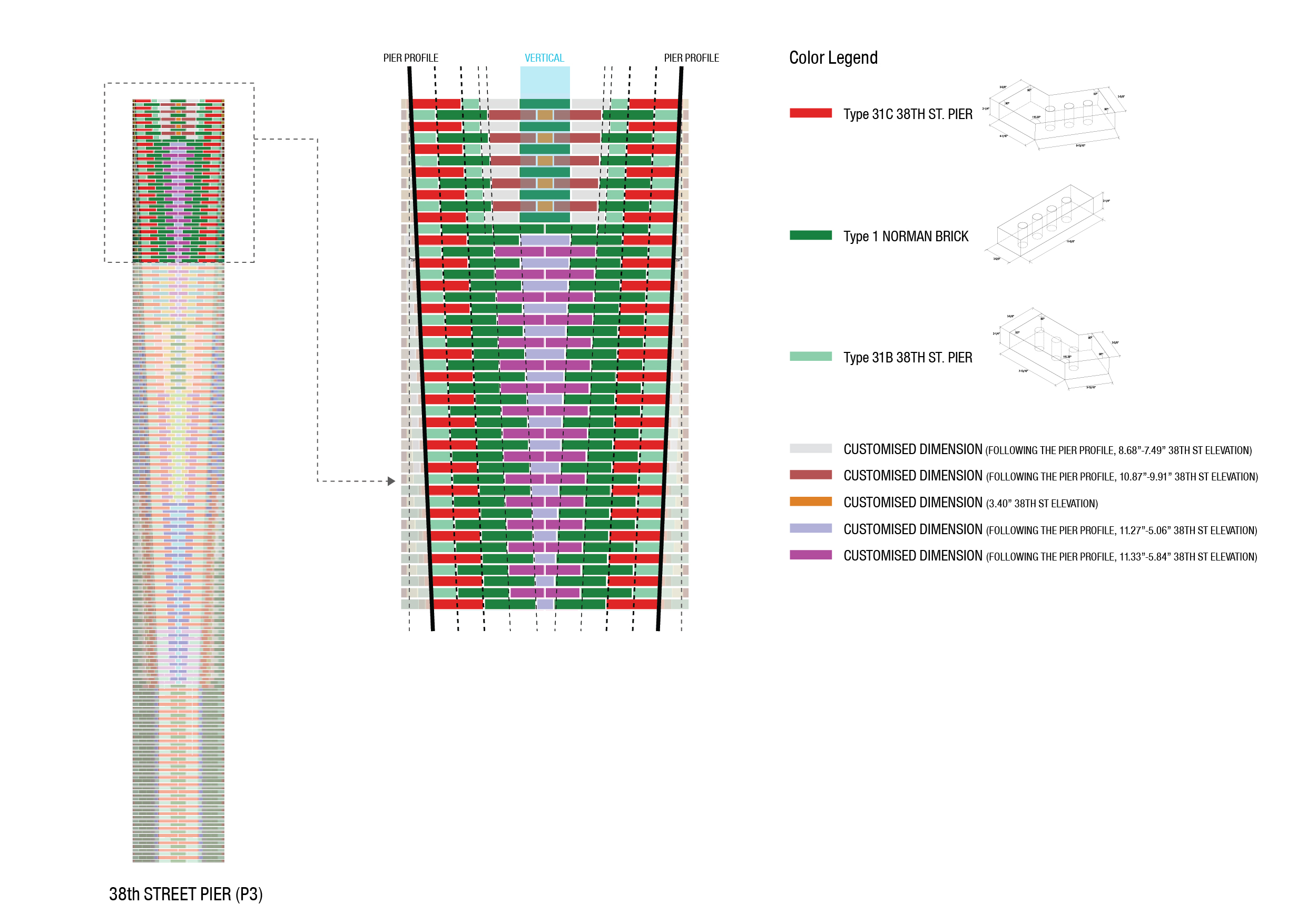

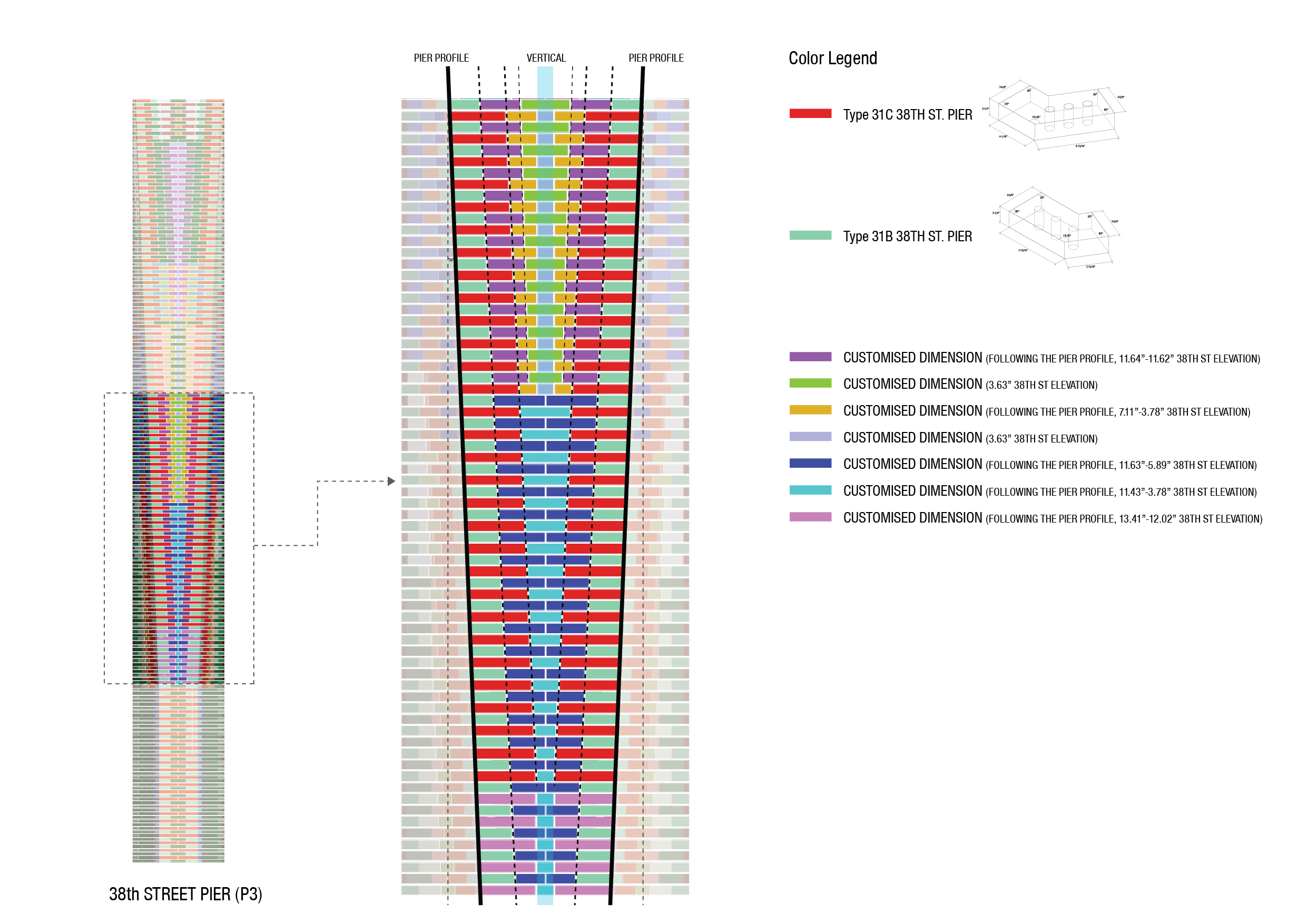

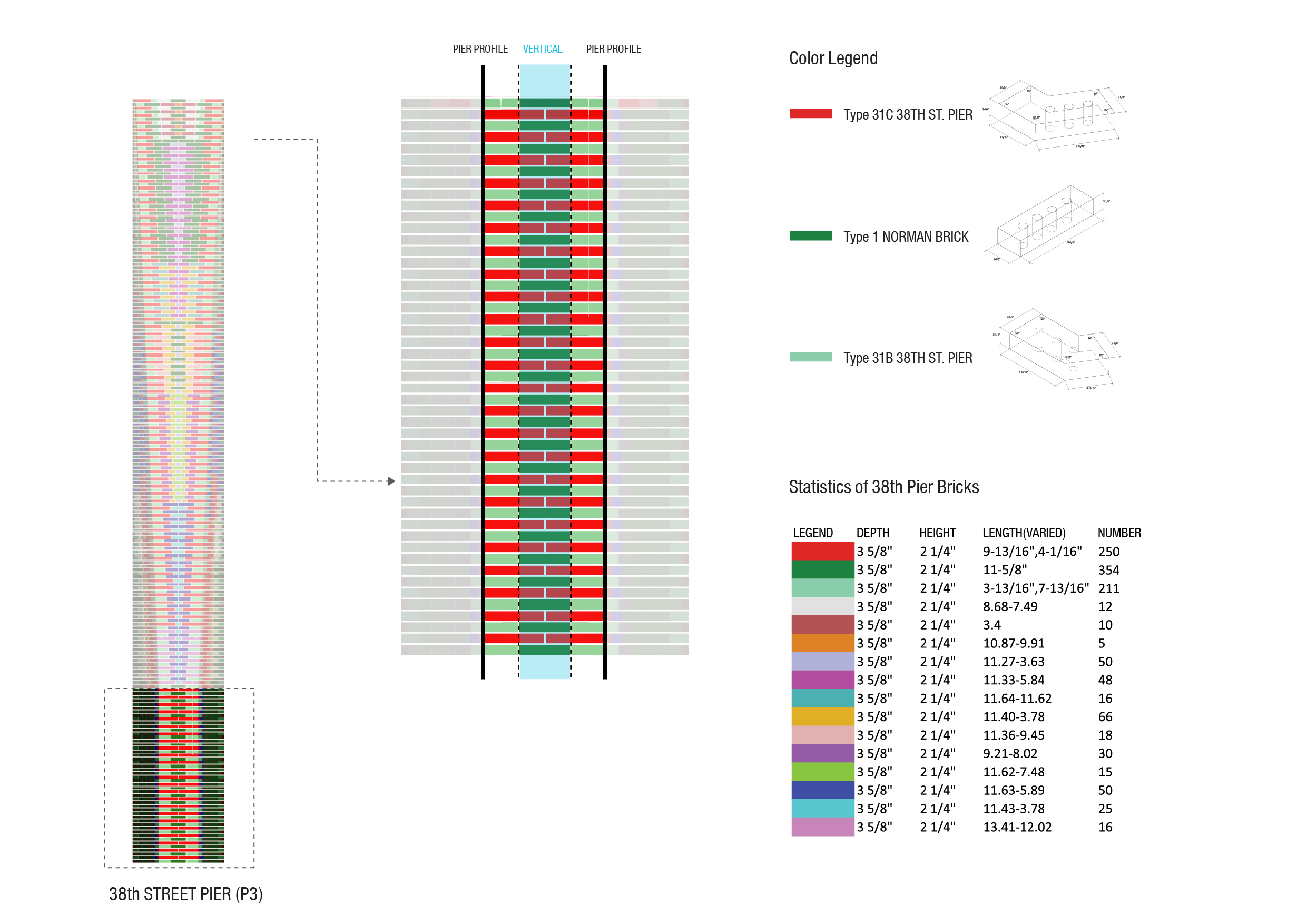

Modelling the Custom GeometryAs part of our analysis we decided to digitally model one of the PIERS (P3 – 38th Street Elevation )

• Modeling every single brick in order to virtually build the Pier prior to its physical construction.

• Every brick was identified as a separate unit and a separate building element ( with its own dimension and profile)

• This was completed using Rhino -‐ unfortunately we could not tag data to the figure of every brick

• This work flow ( which another designer could use to model their own custom geometries) would, if built into an spatial and mathematical algorithm offer the most advanced capacity to both designer and builder.

• Being able to identify every brick with data – size, profile, color, glaze, etc. – would be of vast benefit to designer, general contractor and sub contractor.

By having modeled the entire Pier both Designer and Builder have a numeric count of the typical units as well as tally of all of the super custom pieces. This allows both parties to know early on what the material demands of the project are, facilitating the manufacturing of the brick and its installation.

Conclusion and Next Steps

Conclusion and Next StepsInformation capture was nonexistent during the design and construction of Huntsman Hall

• None of the participants were able to record or code any of the custom processes in which they were involved.

• While KPF had a dedicated person in the firm solely responsible for coordinating all of the masonry design calculations ( with structure, openings, and exterior and interior wall details) none of this information was coded for transfer onto a future project.

• With the loss of this person in the firm so to, was there a loss of the information.

• Similarly, subcontractors Lepore and Sons did not record any of the on-site innovation which they developed in order to execute the custom installation responses required for this particular project.

• As such, there was no knowledge capture for either of the consultants, or for the industry in general.

• None of the information generated through the project will be transferable in the future to help custom projects. As a result, this represents an important loss of information and knowledge for the unit masonry industry.

This represents a huge loss of knowledge and financial capital for the industry

And yet, currently available BIM tools poorly support the Architect and Mason in completing custom masonry projects, nearly 15 years after Huntsman Hall was completed.

Needed is :

1. Access to software based techniques for identifying the systemic information that exists in complex geometries but which are useful for increasing the replicability of formal innovation.

2. The ability to use and integrate building element definitions and dimensions (of typical unit masonry) when designing walls.

3. The ability for a custom conceptual mass to be ‘intelligently” constrained (angles and dimensions) by unit masonry dimensions .

4. The ability to position openings in walls with the openings being intelligent as to the pattern and bonding information of their host wall.

5. The ability to more easily model each masonry unit as a single element for custom modeling purposes ( as in the example of the single pier).

Next Steps

Reviewing the way in which structural modeling of the custom masonry components could be better supported by BIMs.